Automated processes to increase your production

We create solutions for companies that need to improve or implement automated processes, maintain or update the ones they already have.

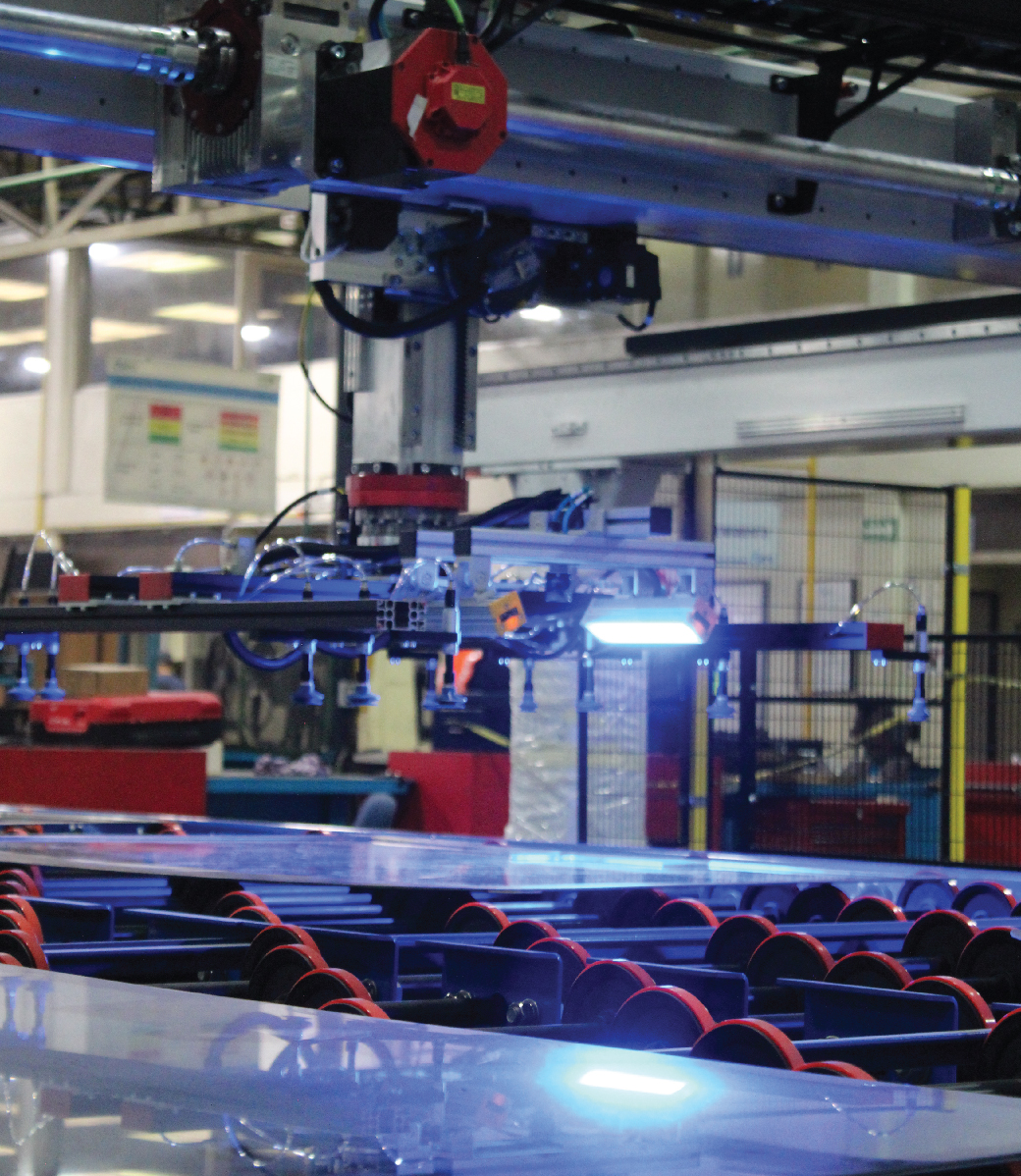

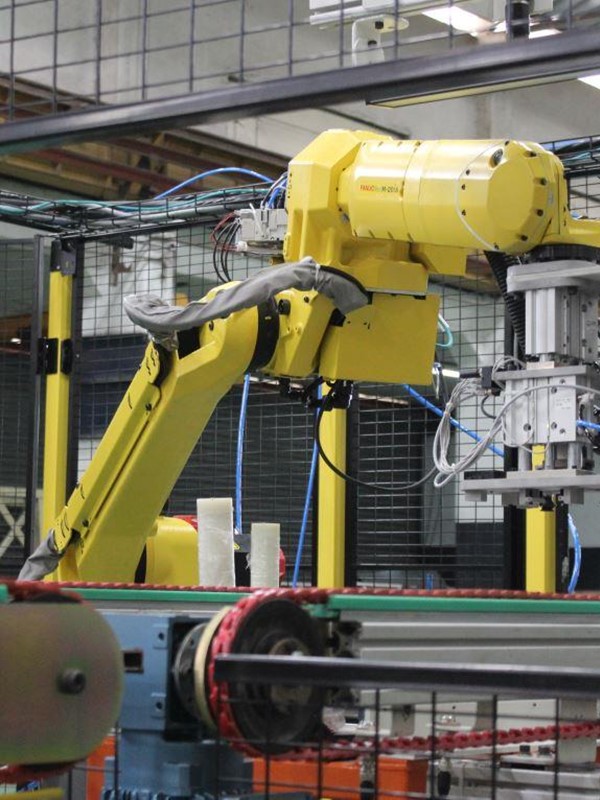

We design and manufacture robotic cells and automatic equipment for material handling and palletizing.

We work hand in hand with our customers in order to create automated production systems tailored to their needs.

Glass

Metalmechanics

Plastic

Mining

FAMA products to improve your automated processes

We use state-of-the-art technology for the development of automated systems that increase the performance and quality of your manufacturing.

In our portfolio you will find:

They are used for different material handling processes, such as product cutting, seal and glue applications and adaptive tooling technology, as well as for material dispensing or removal, quality testing, machine tending (automated operation) and cobots (collaborative robots).

Our assembly stations allow the collection of data such as torque of applied fasteners, installed fasteners, selected tooling, time to complete an assembly, scanned parts and applied product labels.

We design and implement machine vision systems for quality control inspection, part typing and control. We handle from poka-yoke inspection tables for real time error identification and accessories, to complete systems at the end of the line and robotic inspection cells.

We have equipment for assembling, sealing, bagging or capping products in large quantities with mobile option, pallet or unit delivery and manual or automatic unloading, for different types of pre-formed packaging: cardboard boxes, thermoformed plastics, etc., with packaging capacity up to 500 pieces.

Integral solutions where we take care of all the stages of a project, from planning and design to implementation, final delivery and after-sales services.

Our services ensure optimal and continuous operation of robotic cells by providing inspections, preventive maintenance, repairs and technical assistance as needed, maximizing efficiency and equipment lifetime.

Involves constant, real-time monitoring of systems, devices or processes through online connections. This enables early problem detection, data analysis and informed decision-making remotely, optimizing performance, reducing downtime and improving operational efficiency.

Learn about our services

We offer control and automation solutions in turnkey projects, precision manufacturing and development of specialized applications for the industry.